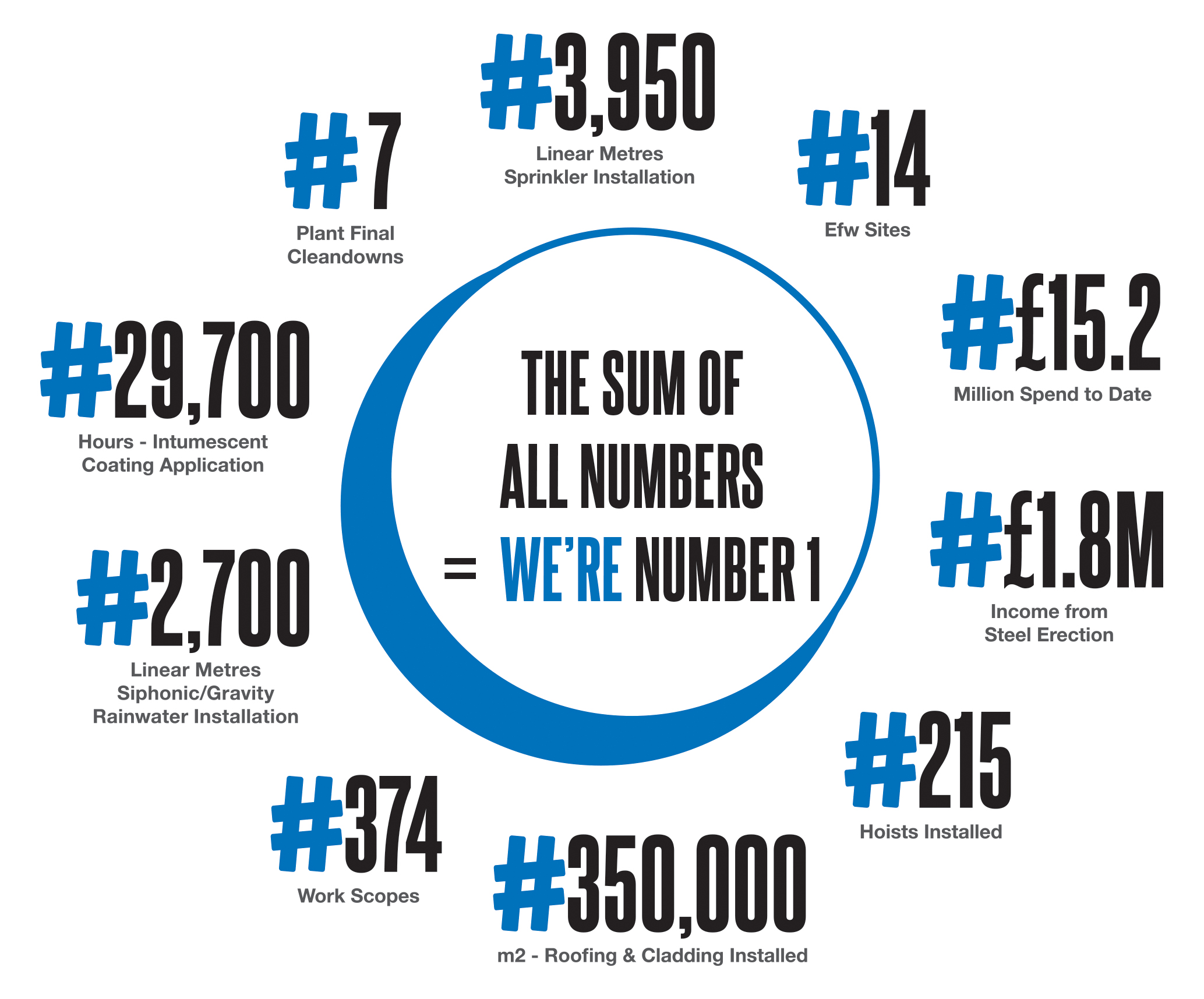

Think Access Group Ltd. is one of the UK’s most experienced rope access contractors supporting the construction and commissioning of Energy from Waste (EfW) facilities. Operating from our four offices — Bonnybridge, Bootle, Scunthorpe, and Faygate — we’ve delivered specialist works on over 14 different EfW and biomass plants nationwide.

From pre-handover clean downs to sprinkler installations, structural steelwork, and siphonic drainage systems, our teams work where others can’t — safely, efficiently, and without the disruption of traditional access methods. We operate in high-risk, high-complexity zones where traditional access has already been dismantled, commissioning has begun, and time is of the essence.

As a proud IRATA member company, our technicians are trained to the highest international standard. We maintain Level 3 supervision on all sites and deliver works under audited rope access procedures. But rope access is only part of what we bring. Our teams include qualified welders, painters, fitters, and snagging specialists — capable of executing technically demanding tasks at height, on time, and on spec.

Through our national framework agreement with Kanadevia Inova (formerly Hitachi Zosen Inova) — one of the UK’s most prominent EPCs in the EfW sector — we have become a go-to rope access partner for some of the country’s largest and most ambitious infrastructure projects.

Our presence is typically required between mechanical completion and final client handover, where multiple trades are working simultaneously, and access is limited. This is where rope access offers unbeatable value: minimal disruption, fast setup, and complete coverage of internal and external assets.

With over nine full-plant clean downs completed, and hundreds of additional rope-based scopes successfully delivered, Think Access Group Ltd. has demonstrated time and again that we are more than a subcontractor — we are a trusted delivery partner.

Our work consistently supports critical path activities, from snagging and envelope sealing to commissioning-stage MEP support. We integrate into multi-disciplinary environments with zero delay, zero compromise on safety, and zero tolerance for missed detail.

Whether we’re cleaning silos in Westfield, installing sprinkler brackets in Slough, or sealing cladding penetrations in Brockwell, we approach every job with the same mindset: get it done safely, cleanly, and without delay.

Why Rope Access is Critical to EfW Construction Success

Energy from Waste plants are high-value infrastructure assets with incredibly tight construction and commissioning timelines. As the final stages of mechanical and electrical installation converge with snagging, cleaning, sealing, and fire testing, one problem emerges: access.

Scaffolding has usually been removed. MEWPs are no longer viable. Civil handover deadlines are looming. That’s where rope access comes in.

Rope access provides immediate, unintrusive, and fully adaptable access across every area of a facility — internal and external. From turbine hall roofs and boiler platforms to tipping halls, silos, chimneys, conveyors, stairwells, and pipework, our teams are able to access, inspect, repair, clean, paint, and install systems wherever they’re needed.

Our operatives don’t just climb — they weld, seal, paint, tighten, adjust, align, and assemble. Whether it’s working with other trades or leading a specialist scope, we embed ourselves into the delivery environment, supporting the EPC and principal contractors on time-critical packages.

This is especially important during the final 4–8 weeks before client handover. It’s here that Think Access adds the most value — supporting inspections, fire tests, snag rectification, coating and ductwork installation, and structural steel finishing.

7 Full Plant Clean Downs (and Counting)

One of the most in-demand services we provide during the construction phase of EfW projects is the full internal and external clean-down. These take place in the final 2–6 weeks prior to handover and serve to remove debris, construction residue, and contaminants across the entire plant envelope.

Think Access has successfully delivered over seven of these complete plant clean downs — across boiler houses, turbine halls, tipping bays, silos, stair towers, platforms, ductwork, and more.

Using rope access, our teams descend into hard-to-reach structures to hand-clean surfaces, vacuum debris, apply protective coatings, and prepare systems for client walkthroughs. Clean downs are typically part of the critical path and must be completed to an exacting standard, often in compressed timelines.

We frequently coordinate with multiple trades to deliver these scopes without interfering with commissioning activities. This often includes work at night or in parallel with live electrical and mechanical works.

Our teams bring all required equipment — from industrial vacuums and chemical cleaning products to rescue systems and PPE — and operate under strict IRATA procedures with daily reporting and supervision.

Project Highlights: Trusted Across the UK’s Energy from Waste Sector

Brockwell Energy – South Lanarkshire

The largest and most complex rope access deployment in our company’s history.

Think Access Group Ltd. delivered a full-spectrum package at Brockwell Energy’s EfW facility — working across structural, MEP, envelope, and cleanliness scopes during the construction phase. We provided:

- Installation support for siphonic drainage systems across multiple roof levels

- Steel erection assistance at height, including bracket and anchor positioning

- Sprinkler head installation and pipe alignment via rope

- Internal and external cladding inspection and snagging

- High-level plant clean down prior to client acceptance

- Visual finishing and sealant remediation

Newhurst ERF – Leicestershire

At Newhurst, we delivered one of our most varied rope access packages, spanning:

- Silo tank cleaning

- Ridge cap repairs

- Siphonic drainage alignment

- Structural and duct sealing

- Sprinkler installation access support

- A complete internal clean down across the facility

Ferrybridge FM2 – Yorkshire

- Final bolt inspections

- Structural seal reviews

- Reactive snagging

- Pre-inspection visual cleaning

Westfield ERF – Fife

- Silo and duct cleaning

- Roof vent sealing

- Final snagging of external cladding

- Rope-based inspections during commissioning

Riverside EFW – Sunderland

- High-level window and panel sealant

- Ridge cap snagging

- Rope-based QA support across cladding envelope

Slough EFW – Berkshire

- Siphonic drainage installation

- Window sealing

- Sprinkler bracket positioning

- Internal clean down around installed systems

Ferrybridge FM2 – Yorkshire

- Final bolt inspections

- Structural seal reviews

- Reactive snagging

- Pre-inspection visual cleaning

Avonmouth EFW – Bristol

- Plant cleaning

- Cladding punch lists

- Roof sealing

- Ridge and vent access

Rivenhall IWMF – Essex

- Cladding inspections

- Siphonic drainage installation

- Pipe sealing and finishing

- Clean down for commissioning

Kemsley EFW – Kent

- Rope access inspections

- Drainage and MEP support

- Sprinkler and siphonic interface checks

- Cladding/Roofing work

Skelton Grange – Leeds

- Rope-based sealing

- Ridge inspections

- Final duct sealing and visual cleaning

- Internal snagging

Kanadevia Inova (formerly Hitachi Zosen Inova)

Think Access Group Ltd. operates under a UK-wide rope access framework agreement with Kanadevia Inova — one of the UK’s most influential EPCs in the EfW sector.

Across multiple projects, we’ve delivered:

- Final plant clean downs

- Sprinkler and drainage system installations

- Steelwork access for bolt inspection and bracket mounting

- Snagging and visual QA

- Sealant remediation at height

Why Think Access?

Choosing the right access partner during the construction and commissioning phase of an Energy from Waste project is critical. At Think Access Group Ltd., we bring more than just IRATA-certified rope access technicians — we bring a full-service, construction-savvy team that understands how to integrate with your programme, meet your deadlines, and exceed your quality expectations.

- IRATA Member Company – We maintain the highest safety standards in the industry through IRATA membership, regular audits, and advanced-level technician supervision.

- Proven Experience – With successful project delivery at over 14 major EfW and biomass facilities across the UK, our portfolio speaks for itself.

- Construction-Focused Delivery – We specialise in construction-phase access support, especially during the final weeks before handover, when scaffold has gone and time is tight.

- Multidisciplinary Skill Sets – Our technicians are more than climbers — they’re welders, painters, fitters, and snaggers, able to work directly on steelwork, cladding, M&E installations, and more.

- Responsive and Scalable – With teams operating out of Bonnybridge, Bootle, Scunthorpe, and Faygate, we offer nationwide coverage and rapid mobilisation for projects of all sizes.

- Trusted by Industry Leaders – Our framework agreement with Kanadevia Inova and repeat business with top EPCs is a testament to our reliability and performance.

Whether it’s a full-plant clean down, sprinkler install, siphonic system fit-out, or last-minute snag rectification, Think Access Group Ltd. is the contractor that steps in when others step back.

Ready to get your project over the finish line?

Contact Think Access Group Ltd. today to discuss your rope access requirements — and let’s deliver your next EfW project with confidence.