Client Overview: BWSC is a leading energy provider known for its commitment to efficiency and safety. Their annual shutdowns are critical for maintenance and inspection to ensure uninterrupted operations and safety compliance.

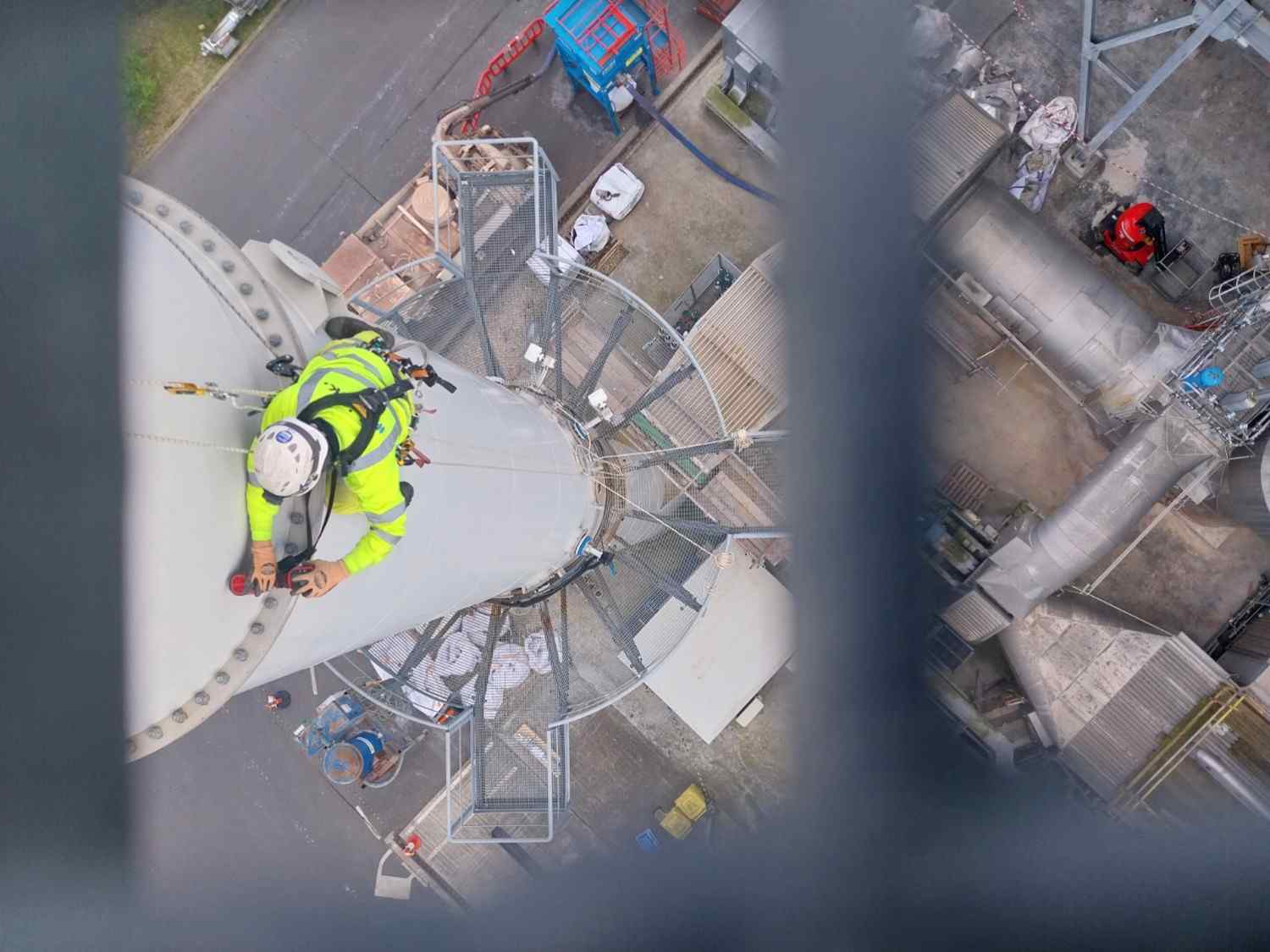

Client’s Brief: For the seventh consecutive year, #thinkaccess was entrusted with the comprehensive inspection of BWSC’s stack. The client’s confidence in #thinkaccess stems from our ability to deliver detailed reports and conduct thorough inspections.

Project Scope and Solutions: The project encompassed a range of essential inspections crucial for the power station’s continued operation:

- Check Torque Settings on Bolted Flange Joints: Ensuring the integrity of connections crucial for safety and performance.

- Inspect Oil-filled Damper: Assessing the condition of critical components for optimal functionality.

- Inspect Anti-Collision Lights: Vital for aviation safety and compliance.

- Inspect Three Landing Platforms: Ensuring safe access for maintenance personnel.

- Inspect Lifting Davits: Essential equipment for maintenance and emergency procedures.

- Inspection of Ladder Access System and Certification: Ensuring safe and compliant access to all gantries.

#thinkaccess employed rope access techniques to offer a comprehensive solution, providing the client with the assurance that both the stack and associated access systems were thoroughly inspected.

Project Results: The #thinkaccess team successfully completed the inspection within five days, meeting the client’s tight schedule demands. The culmination of their efforts was a detailed report delivered within seven days of project completion. This report provided BWSC with invaluable insights into the condition of their stack and associated infrastructure, enabling informed decision-making regarding maintenance and future investments.