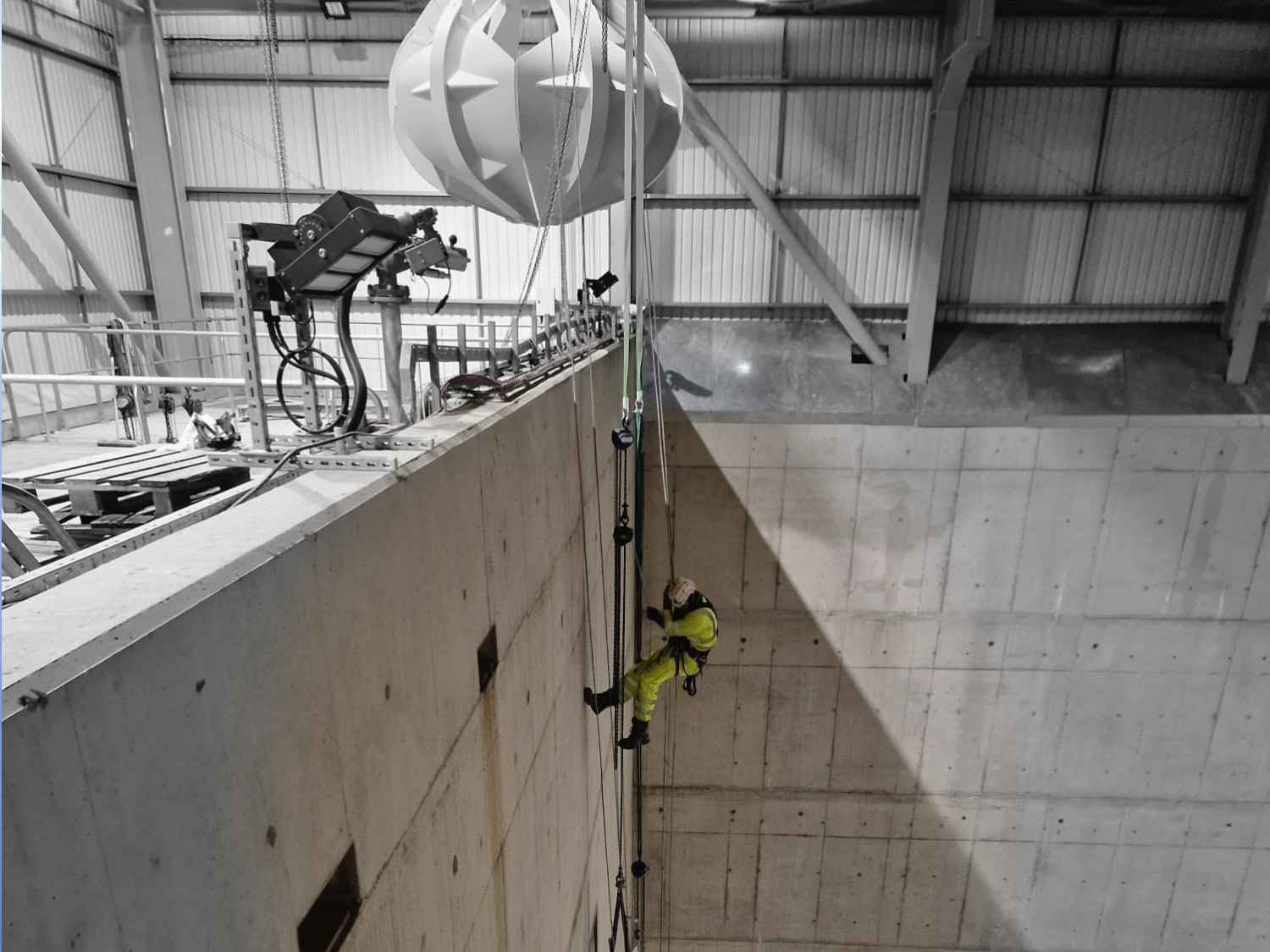

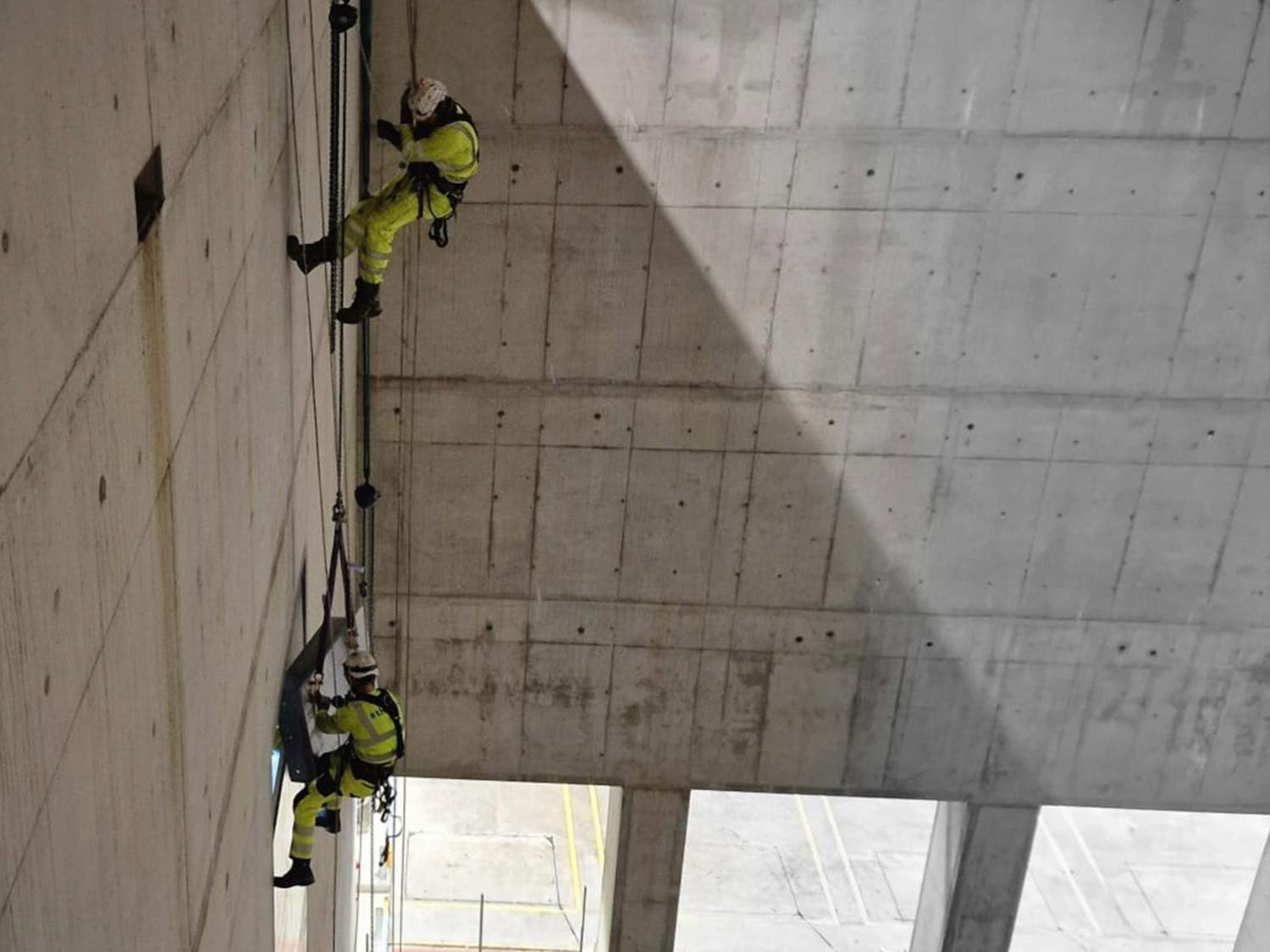

Given the unique location and demands of the project, we opted for the dynamic method of rope access over traditional scaffolding. This not only saved costs but also allowed us to navigate the intricate space with precision. As ever safety and efficiency were our top priorities .

The selection of robust, heavy gauge steel was imperative to ensure durability and longevity, as both the steel and plates could potentially come into contact with the waste bunker crane. We tackled the task head-on, installing a total of 8 substantial steel pieces, collectively weighing an impressive 2.68 tons!

Our exceptional 4-person team, composed of highly skilled riggers and a diverse range of IRATA levels, meticulously planned and executed each step of the installation. The result? A seamless operation that met deadlines and stayed well within the budget.

At #thinkaccess, we take immense pride in our commitment to excellence. This project is a testament to our dedication, technical prowess, and innovative problem-solving. We’re pleased to have played a pivotal role in the Earlsgate EFW project, and we look forward to tackling more challenges and achieving new milestones in the future.