Services Provided: Rope access riggers, steel erection, Mewp operatives

Client Brief: The client required the relocation of all sections of structural plating and steel from ground level up to the 20m level of the waste bunker for installation. The primary objective was to create a fully sealed and structurally sound wall capable of withstanding substantial impacts from the waste crane. Additionally, the construction needed to pass an internal smoke test during the handover process.

Project Solution: Working closely with the onsite engineer, Think Access not only executed the installation but also played a crucial role in the planning process. This collaboration ensured the project was delivered both on time and within budget.

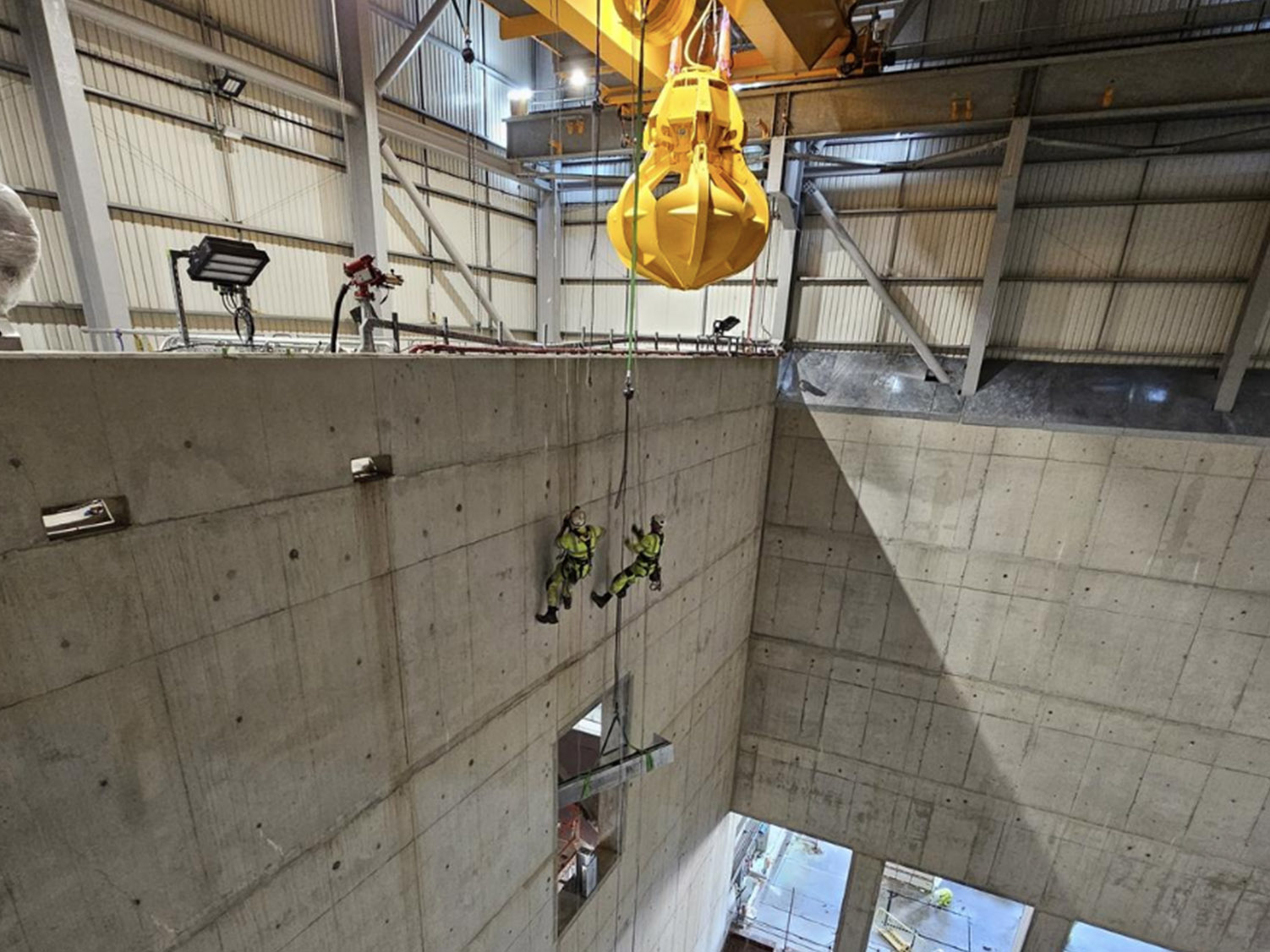

The process involved four rope access technicians, two of whom were qualified riggers. They manoeuvred each section from the laydown area of the 20m level within the waste bunker over the bunker wall and into its final fixed position. Utilising the skill set of the riggers, obstacles were overcome using standard rigging made accessible through rope access.

Once in its final position, the internal team used Mewp to gain access, drilling 12 holes at 300mm deep for each piece. This step required meticulous planning to ensure the equipment could cut through structural steel and heavy-duty concrete.

Project Results: The outcome was a fully sealed and structurally sound steel plate, ensuring no waste or odours could escape. The project was completed on time without any delays, resulting in works coming in under budget.

Safety first: Safety was of paramount importance during the execution of the project, especially considering the ongoing construction activities at the site. Despite the challenges posed by the simultaneous construction work and installation process, #thinkaccess prioritised safety measures throughout the project. The team, meticulously manoeuvred each section of structural steel from the laydown area of the 20m level within the waste bunker to its final fixed position. The collaboration with onsite engineers ensured a comprehensive planning process, addressing potential safety hazards associated with the construction environment. The client praised Think Access for their dedication to safety and effective project management, highlighting the successful collaboration with the entire team.

Client Testimonial: “Working with Think Access closely on previous steel erecting scopes, I was conscious that this project needed not only specialist access but planning and organisation too. The job was run with safety as paramount due to ongoing works still happening onsite, but with time being of the essence. A job well done by all members of the team.”