Client Brief: When Brockwell Energy took over a power plant construction project, they encountered an unexpected challenge. The previously installed lifting beams, critical components of the project, were coated with galvanized paint instead of the standard yellow coating typically used in power plants across the UK.

Services Provided: Painting site-wide of Lifting Beams

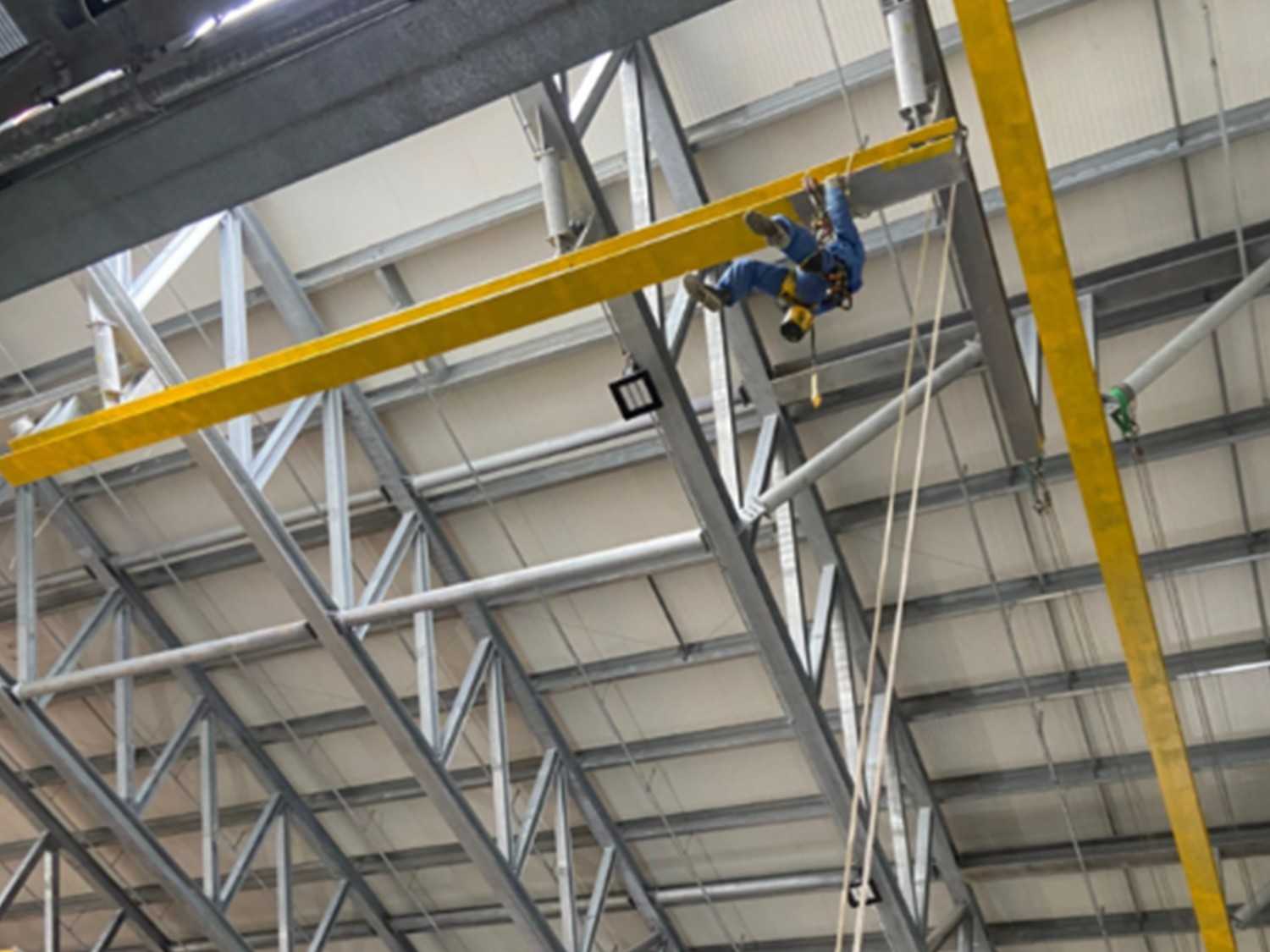

Project Solution: Painting To rectify this issue and ensure the lifting beams met safety and aesthetic standards, Brockwell Energy engaged in a comprehensive painting project. They knew that for this task, a standard paint job wouldn’t suffice. To address the unique circumstances, they enlisted the expertise of qualified rope access painters and collaborated with their supply chain to execute a tailored solution.

The key to the project’s success lay in meticulous preparation. Prior to any paint application, each lifting beam underwent thorough surface preparation. This ensured that the new coating would adhere securely to the substrate, preventing issues such as peeling and corrosion.

To provide the beams with robust protection against the demanding conditions they would face in the waste bunker of a fully functioning power plant, a three-coat system was implemented. This system not only ensured longevity but also enhanced the beams’ resistance to corrosion and wear.

Project Results: The project’s successful completion resulted in the transformation of 105 meters of steel lifting beams. They were taken from their initial galvanized coating to the correct protective coating and color, aligning them with industry standards and safety requirements.

This transformation not only addressed the aesthetic concerns but also ensured the lifting beams would function optimally, even in the harshest operating conditions. Brockwell Energy’s commitment to quality and attention to detail ultimately secured a safer and more efficient power plant construction project.