Project Overview

Client: One of the UK’s Largest Fire Protection Companies

Location: Rookery Energy from Waste (EFW) Facility

Project Duration: Just under 3 months

Services Provided:

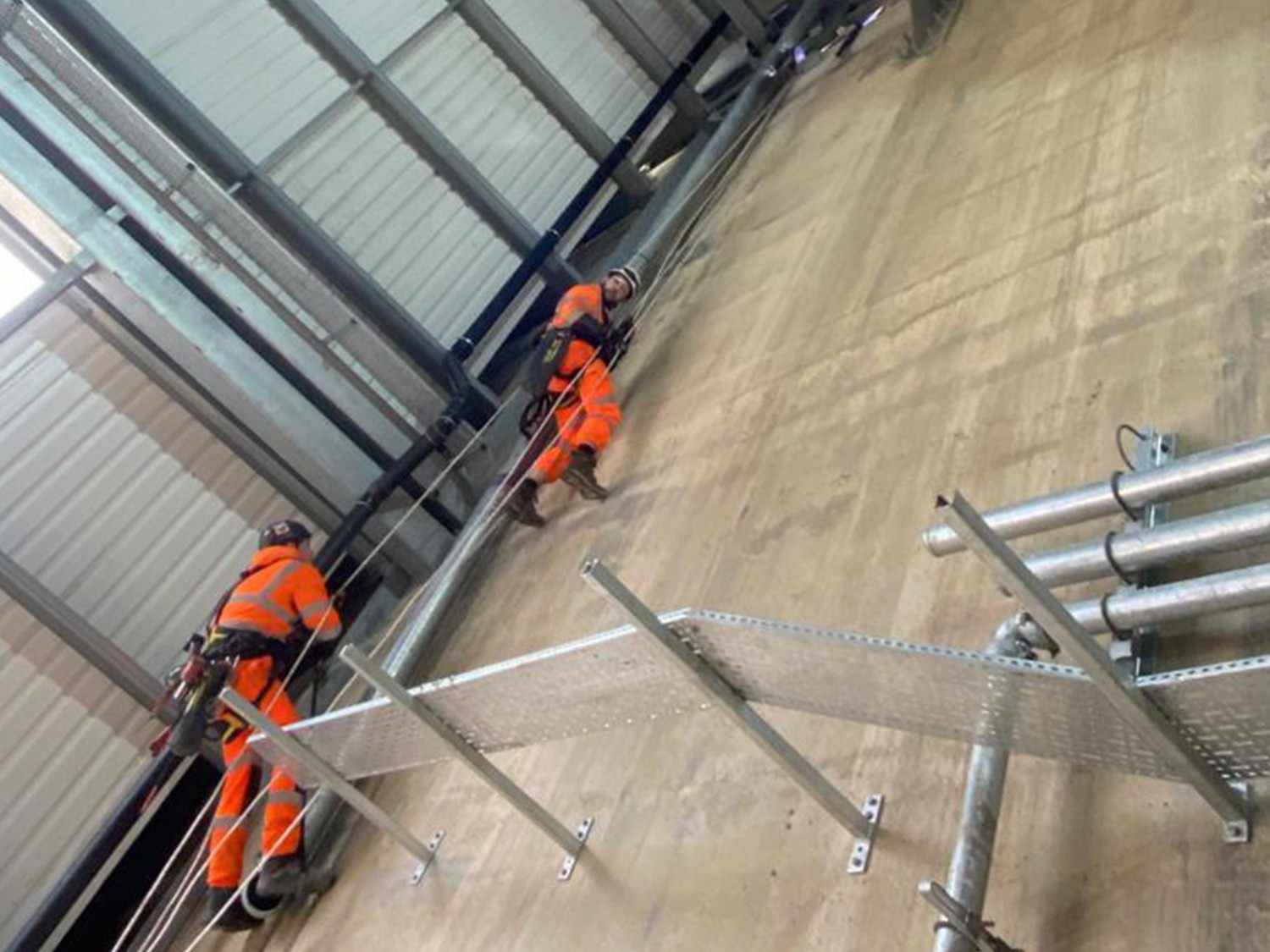

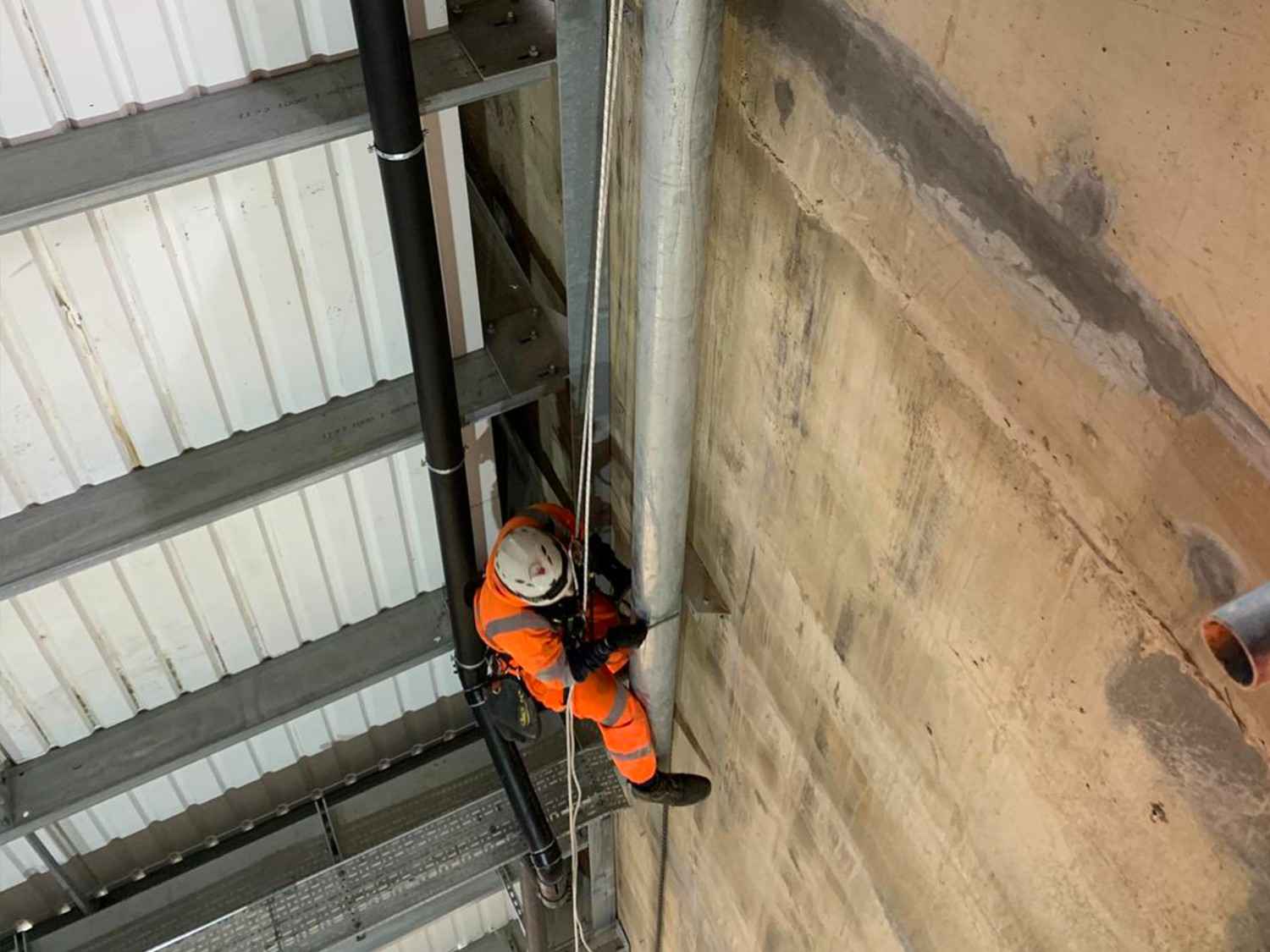

- 4-man multi-skilled rope access team

- Qualified team of pipe fitters/installers

Scope of Work

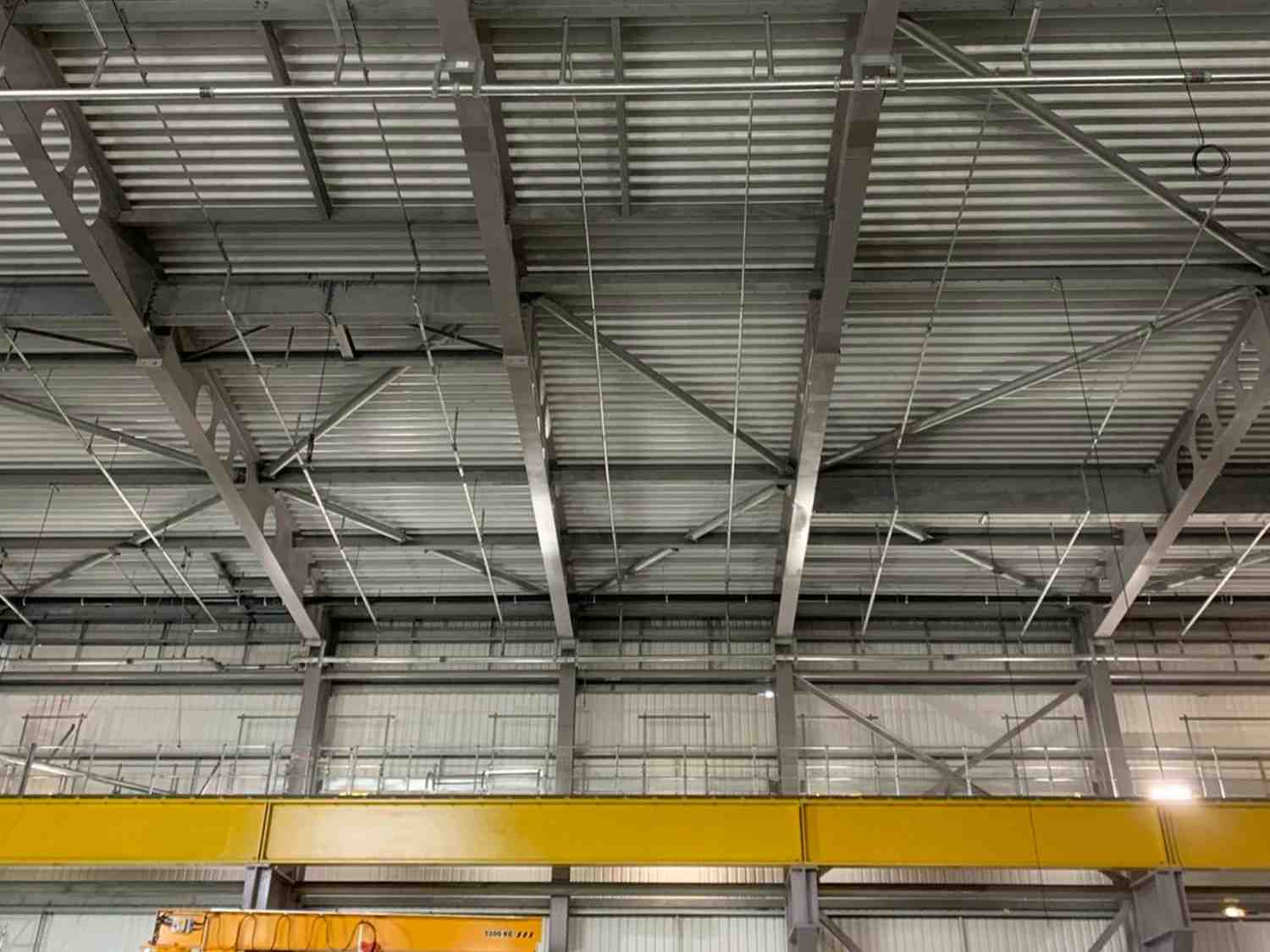

#thinkaccess was contracted to install a comprehensive sprinkler system in Rookery EFW, targeting four high-traffic and critical work areas: the Turbine Hall, Balance of Plant (BOP), Flue Gas Treatment (FGT), and Boiler Hall. The project was essential for ensuring the fire safety and compliance of the facility, which processes waste to generate energy.

Project Solution

Detailed Planning and Execution:

-

- A 4-man multi-skilled rope access team was assembled, alongside a qualified team of pipe fitters and installers.

- Thorough safety briefings and risk assessments were conducted to align with the high standards required in critical industrial environments.

- Leveraging detailed drawings and specifications provided by the client, the team meticulously planned the installation phases to minimise disruption in high-traffic areas.

- Equipment was inspected and prepared to ensure it met all necessary safety and operational standards.

Installation Process:

-

- Turbine Hall: The team installed the primary pipework and sprinkler heads, utilising rope access techniques to efficiently navigate the complex structural layout.

- BOP Area: Coordination with other trades was critical to install the fire suppression system without hindering ongoing operations.

- FGT and Boiler Hall: These areas required precise execution due to the high-risk nature of the equipment. The rope access team ensured all installations were completed with minimal downtime and maximum safety.

Integral Role in Overall Installation:

-

-

-

- Beyond primary installation, #thinkaccess became a vital part of the overall project. The team’s expertise was instrumental in final testing and certification phases.

- Collaboration with the client and other contractors ensured the sprinkler system was fully integrated and operational across all designated areas.

-

-

Project Results

- Completion Time: The project was completed in just under three months, showcasing efficient project management and execution.

- Budget Compliance: The entire installation was completed within the allocated budget, demonstrating cost-effective solutions without compromising quality or safety.

- Operational Success: The Rookery EFW now boasts a fully functional fire suppression system, enhancing the safety and compliance of one of the UK’s major waste-to-energy facilities.

Conclusion

#thinkaccess delivered a successful sprinkler system installation at Rookery EFW, highlighting the company’s capability to manage complex installations in high-risk environments. The project not only met the client’s stringent requirements but also underscored the critical role of skilled rope access teams and qualified installers in achieving comprehensive fire protection solutions.